The Solutions

If all you need are emission concentration measurements

you can use the portable 350-Maritime emissions analyzer that has Type Approval certificate for compliance with MARPOL 73/78 Annex VI, NOx Technical Code and MEPC.103(49), which gives you quickly and efficiently highest accuracy reliable emission measurements that ensure the precise values of O2, CO, NOx, SOx, CO2, flue gas temperature, ambient temperature, pressure, calculated fuel moisture content, and combustion efficiency, in a few minutes, allowing optimum adjustment, data storage/export/printing and thus eliminating guesswork.

350-MARITIME Technical data

| Parameter | Measuring Range | Accuracy |

| °C flue gas | -40 up to 1000°C | max. ±5 K |

| O2 | 0 … 25 Vol% |

Subject to MARPOL Annex VI respective NOx Technical Code |

| CO | 0 … 3000 ppm |

Subject to MARPOL Annex VI respective NOx Technical Code |

| NO | 0 … 3000 ppm |

Subject to MARPOL Annex VI respective NOx Technical Code |

| NO2 | 0 … 500 ppm |

Subject to MARPOL Annex VI respective NOx Technical Code |

| SO2 | 0 … 3000 ppm |

Subject to MARPOL Annex VI respective NOx Technical Code |

| CO2 (IR) | 0 … 40 Vol% |

Subject to MARPOL Annex VI respective NOx Technical Code |

| pabs | 600 … 1150 hPa |

±5 hPa at 22 °C |

| Storage temperature | -10°C up to 50°C | |

| Operation temperature | 5°C up to 50°C | |

| Power supply |

11 … 40 V DC or 110 ... 230 V AC 50/60 Hz |

|

| Buffer battery | NiMH 8,4V/4,5Ah | |

| Electrical power consumption | max. 40 W | |

| Max. positive pressure / flue gas | 50 hPa | |

| Max. negative pressure / flue gas | -200 hPa | |

| Weight (system including case) | appr. 17 kg | |

| Dimensions (case) | 56,5 x 45,5 x 26,5 cm |

Set includes the Analyzer box of 350-MARITIME fitted with: O2, CO, CO2-(IR), NO, NO2 and SO2, incl. gas preparation, differential pressure sensor, 2 temperature probe inputs, data-bus connection, fresh air valve for long-term measurement, integrated battery, integrated combustion air probe (NTC), trigger input, measurement datastore, USB interface, Control-Unit of 350-MARITIME V2, a robust protection case with trolley function (without protective cap in the bottom) - Exhaust gas probe for industrial engines with probe pre-filter, 335mm immersion deptη incl. cone and heatshield, Tmax 1000°C, special hose for NO2- / SO2 measurements, length 5.2m, incl. thermocouple for exhaust gas temperature measurement (NiCr-Ni, length 400mm, Tmax. +1000°C) with 5.4m connection line and additional temperature protection - Connection cable between Control Unit and analyzerbox, length 5m, fast printer with wireless infrared interface, 1 roll of thermal paper and 4 mignon batteries for printing readings out on site - Humidity / temperature instrument 610 - Silicon connection hose (Ø4mm, length 5m) incl. hose connector to exhaust gas probe to measureback pressure in the measurement- Germanischer Lloyd (GL)-certificate

OR

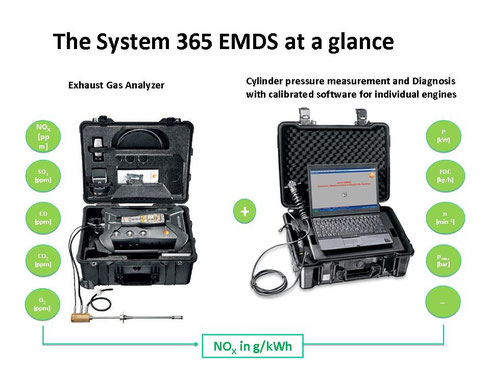

the unique GL approved multi purpose portable 365 EMDS

You can’t manage what you don’t measure

Fleet Performance Monitoring and Optimisation with 365 EMDS

Optimize diesel engine performance for maintenance and fuel consumption benefits without exceeding NOx limits and be in a position to know voyage costs with a user friendly portable approved system and methods. How?

With the unique revolutionary system certified for compliance with revised MARPOL Annex VI & NOx Technical Code by Germanischer Lloyd, the 365 EMDS (Emission Measurement & Diagnosis System) which combines highly-developed hardware and proven concept software.

The 2 probe set consists of a cylinder pressure measurement system and a portable emissions analyzer, the first and only emissions analyzer with marine type approvals (GL, DNV, RR). If the engine data is known, the system can define all parameters necessary for the calculation, and with the help of the intelligent software convert the specific NOx values into g/kWh.

Furthermore the 365 EMDS includes a precise cylinder pressure measurement system which functions without a Top Dead Centre decoder and performance pressure recording, making it very robust and simple.

The 365 EMDS system offers you even more features:

Via a diagnosis function, it provides measurement data on the engine settings, the status of the cylinders and subsystems, and gives useful tips on the optimum setting and maintenance of the entire engine system. This results in a considerable potential for fuel savings. In addition to this, malfunctions in the engine system can be recognized early and eliminated before reaching a critical stage, or cost-intensive repairs (possibly even at sea), become necessary.

You can lower operating costs and protect the environment with the 365 EMDS system.

The unique portable measuring systems with certified measurement technology according to MARPOL Annex VI for NOx in g/kWh, O2, SO2, CO2 and engine diagnosis, can be used for any main and auxiliary diesel engine on board.

This state of the art latest development, of the portable 365 EMDS system offers the following main advantages:

- Fast and substantiated measurements during operation with only 2 probes.

- No installation necessary or interference with existing infrastructure.

- Easy handling by the crew

- Flexibility - enables measurement of all 2 and 4 stroke engines (main engine and diesel generators) with one system

- Highly accurate measurement of FOC of single cylinders and the entire engine

- Fuel & NOx optimized engine with resulting fuel savings

- Exact knowledge of the current specific NOx emissions in relation to the current limit value and test bed data

- Additional measurement parameters such as O2, CO, CO2 and SO2 in one instrument

- Sophisticated engine diagnosis that offers a multitude of useful information about the condition of engines and subsystems

- Restore poorly performing engines to top efficiency

- Power Measurement and Performance

- Highly accurate cylinder pressure measurement

- Comparing easily actual engine performance data with data from FAT

- Detection of propeller efficiency reduction or/and increase of resistance (hull)

- Checking installed fuel oil flowmeters on board

- Verifying shop tests

- Verifying sea trials

- Methodology used approved & certified by GL

- Performance information provided is equivalent (concerning accuracy) to the following systems:Torque meter, Flow meter, Conventional cylinder pressure indicating equipment, TDC markers or encoders.

- Obtaining measurement results by email in less than 30 minutes

- Long term investigations and trend from Head Office

- Provides embedded simulator to define the optimum operating operating point of the engine.

- Providing measurements and a simulator for SEEMP (Ship Energy Efficiency Management Plan) with least possible investment cost.

- Assist with Energy Efficiency Design Index

- Strengthen the Green Image of your Company

- Your company will be ready for future forthcoming regulationsand requirements.